Altronics Inc.

- Ignition Systems CPU-95

- Engine Controls

- Control Panels

- GTI Bi Fuel System

Service Features

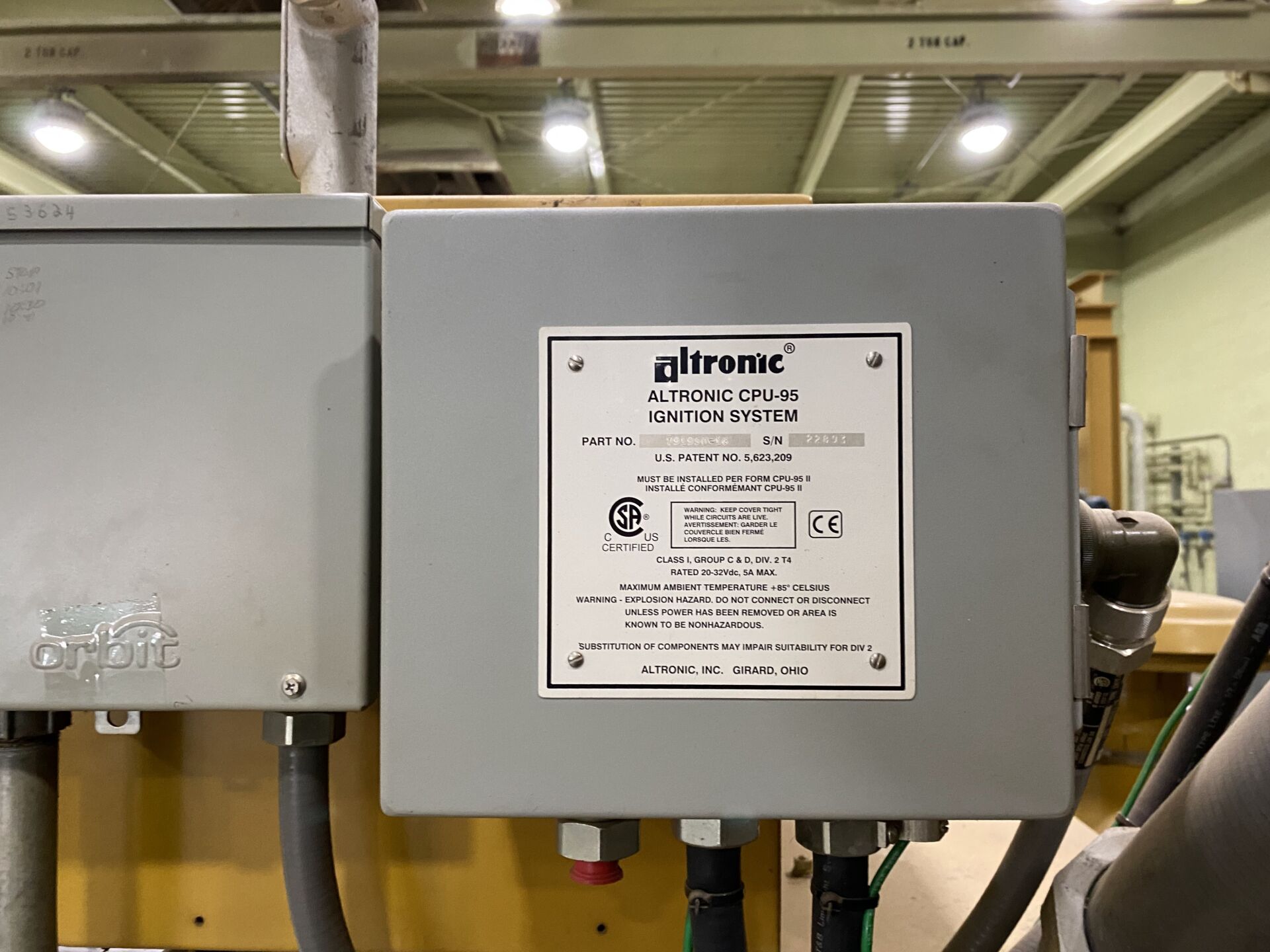

Altronic CPU-95

The Altronic CPU-95, a 24 Vdcpowered, microprocessor-based digital ignition system designed for application to medium-range industrial gas engines. Advantages include a full-featured user display and interface, spark characteristic control, advanced timing adjustment options, serial communications, and state-of-the-art diagnostics. Full access to all CPU-95 operating data and control functionality is available through an advanced, user-friendly Display Module as well as via a PC operating the provided CPU-95 Terminal Program. Both options display essential engine and ignition data such as RPM, timing angle, spark energy level, and diagnostic messages, along with global and individual cylinder timing adjustments, spark energy level control, overspeed setpoint and double strike/extended spark (VariSpark variant) selectability. Additionally, the Enhanced Display Module features extensive spark reference number graphing and trending. Patented CPU-95 diagnostics and prognostics (predictive diagnostics) supervise all ignition system-related functions. The secondary analysis capabilities detect shorted spark plugs and leads, as well as spark plugs that exhibit high voltage demand or are not firing at all. A display of the relative voltage demand of each spark plug is provided, allowing spark plug changes to be predicted and scheduled. Module and pickup operation, timing input, and primary output functions are also monitored for operation within preset limits.

GTI Bi-Fuel System

The GTI Bi-Fuel System operates by blending both diesel fuel and natural gas in the combustion chamber. This is achieved using a fumigated gas-charge design, whereby natural gas is pre-mixed with engine intake-air and delivered to the combustion chamber via the air-intake valve. The air-gas mixture is ignited when the diesel injector sprays a reduced quantity of diesel fuel into the chamber. This diesel "pilot" acts as the ignition source for the primary air-gas combustible mixture. Because the Bi-Fuel System utilizes the OEM air-intake and diesel injection systems, no internal engine modifications are required for installation. Other systems also include engine controls and control panels which are poised for efficient and effective work output and ensure the safe operation of the systems.